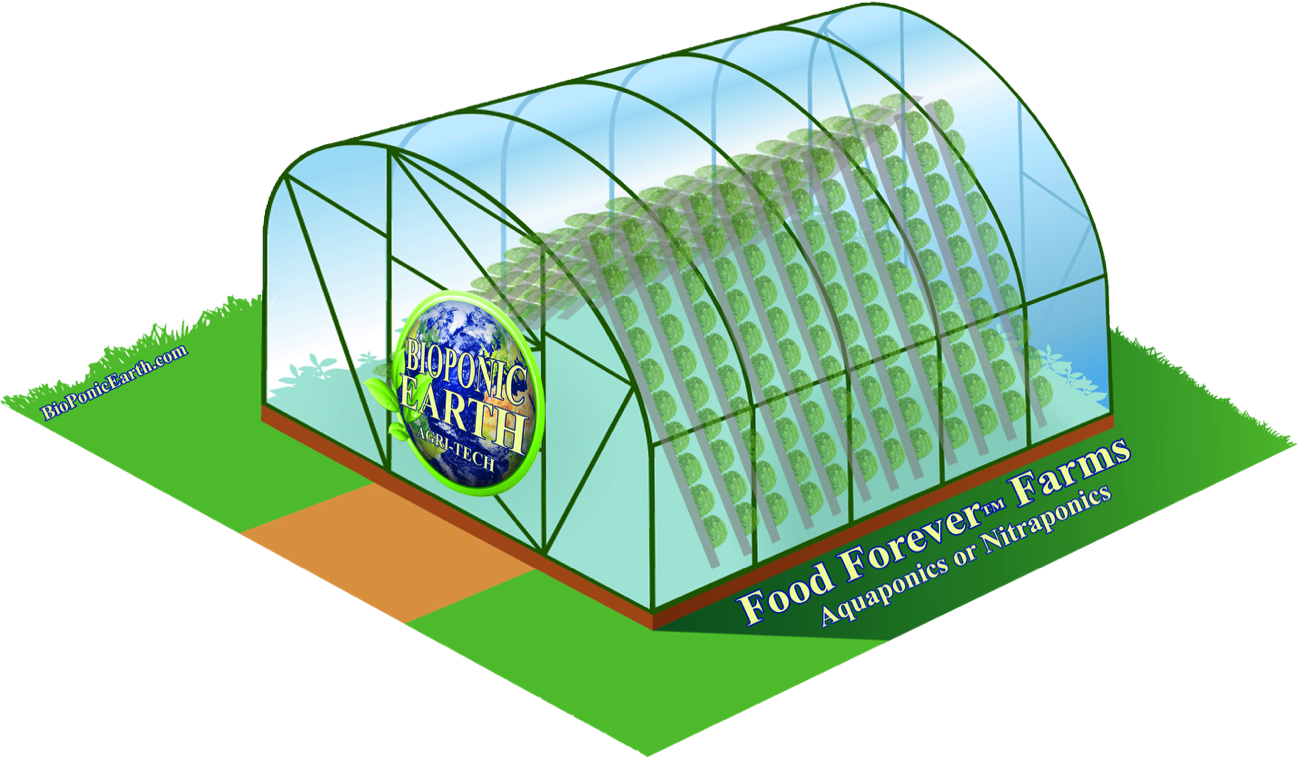

What Is A Food Forever Farm?

Food Forever Farms are placed within Climate Controlled Greenhouses or Growhouses to grow healthy, pesticide and GMO Free Food. Our near Vertical Leafy Green Growing Ducts we call Duffy Ducts after their designer, Oliver Duffy, can be up to 10' tall and make Vertical Growing easy, inexpensive and make planting and harvesting as efficient as possible.

Who Builds The Food Forever Farm?

The Farmer/Entrepreneur builds the Farm after purchasing a one-time Licensing Agreement from BioPonic Earth, LLC and receiving a Customized and Detailed Analysis of the Farm Layout, Specifications, Materials and Components List (some of which are manufactured by BioPonic Earth). Included in the Licensing Package are Billable Consulting Hours that include on site Consulting regarding the building and assembly of the Farm once the Greenhouse or Growhouse is constructructed and fully ready to receive its Food Forever Farm Growing System. Off-site, Phone or Zoom Consulting is also included in Billable Hours which begin once the Licensing Fee is paid and the Farm Design initiated. The final stage of Billable Consulting/Training Hours take place once the Farm is completed and the Employee Training Program begins.

This Analysis & Specifications Document is based on many factors inclucing:

1. Is the Farm in a Greenhouse or Growhouse?

2. Is the Farm doing Aquaponics or Nitraponics? (At this time, we are only Licensing

3. What is the Farm Growing? Aquaponics Food Forever Farms)

4. Is Natural Gas available to the Farm?

5. Within what kind of Climate is the Farm located?

6. How big is the Farm?

7. Are there plans for Farm expansion?

8. Where is the Market for the Farm's Products?

9. Will the Farm offer a Community Supported Agriculture (CSA) Program?

10. What is the Altitude of the Farm?

11. How many Employees will the Farm be supporting?

12. What are the Electrical requirements and Rates?

What Are The Components That Make Up A Food Forever Farm?

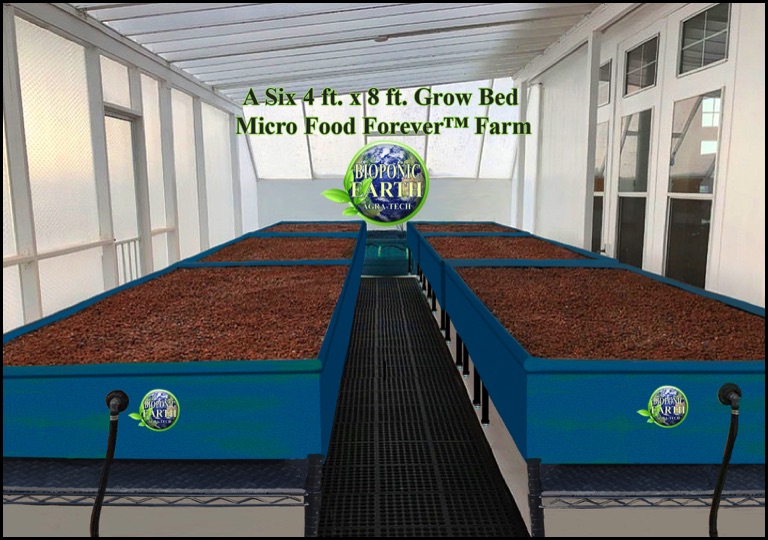

2. Stage 1 Horizontal Duffy Duct System: It's important to note we are not talking about Deep Water Culture Grow Beds as seen in the photo below. Our Water Culure Growing Area is a proprietary design consisting of individual enclosed round troughs all configured into a single System similar to NFT troughs. The water is very shallow, and it is unique in the field. We call it our Stage 1 Horizontal Duffy Duct System.

Traditional Deep Water Culture Beds (DWC) like Deep Media Beds are staples in the new agriculture. They are long troughs with pond liners full of water and Polystyrene Rafts floating on them. Seedlings growing in Net Pots are placed in the holes in the Polystyrene so the roots float in the nutrient rich water, which is created by the fish effluent if you're running an Aquaponics System or by BioDigested Fish Food or other high-nitrogen content organic plant based feed stock if you're running a Nitrapoinics System.

DWC Growing Rafts work great as you can see from the photo below, but they use a lot of water and electricity to operate. If they are near the ground like most of them are because water is heavy, working in these Grow Beds can be a real boon for chiropractor's. There are several problems incurred by using this method. There is a considerable amount of water being moved down the length of the grow bed. It takes a fairly large pump and its associated electricity to move this water if done at anything other than a leisurely pace.

If the water is moved slowly in order to reduce pumping requirements, then the time it takes the water to travel the length of the trough allows for a change in the water’s chemistry from one end to the other. This then means that plants at one end of the flow trough are subjected to a different water quality than those at the other end. Changes from end to end include temperature, pH, dissolved oxygen content and nutrient value. To mitigate the loss in dissolved oxygen, air pumps and aerators are often added along the the bottom of the troughs adding infrastructure and energy cost.

If properly designed, water flows through the trough at a rate that insures fairly consistent water quality from end to end. If the trough is long, say 30 meters, then the rate of flow has to be high. Depending on the trough width per planting row, the restriction to flow can vary as the plants grow and the trough requires a slope to compensate for the friction of the trough and the plant roots. By making the trough considerably wider than the plant root, the water can flow through the trough with little plant root interference. Due to this low restriction, the slope of DWC is usually about 100 to 1. Wide DWC troughs can contain multiple rows of plants.

Harvesting DWC Raft Systems requires removing one of the floating Rafts from the System and taking it to a harvesting area.

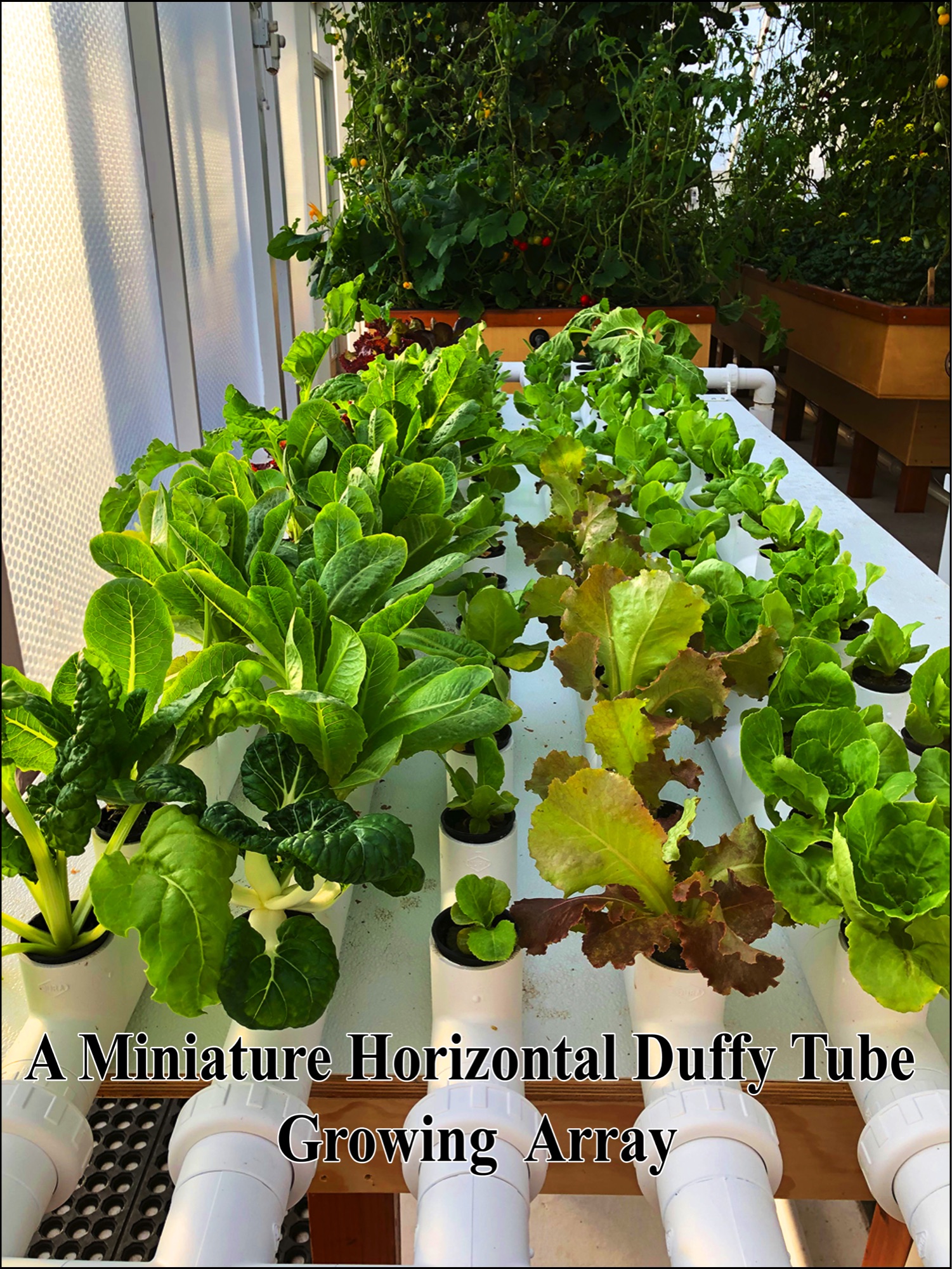

Our Stage 1 Horizontal Duffy Duct System solves all of the problems of DWC Growing Rafts. The photo below is a small Stage 1 Horizontal Duffy Duct Growing System that we are using as the seedling grow out area before placing our plants into our Stage 2 Vertical Duffy Duct System.

As you can see by the photo, this System solves all of the problems of DWC Rafts. There's a supporting table that is 8'x4' built at a comfortable height for planting and harvesting without breaking your back because of having to bend or kneel down towards the ground. This is possible because pounds of water aren't flowing through the System. One small pump does the job of pumping the shallow water through the Tubes. Therefore, the nutrient consistency of the water remains constant and electrical use is diminished. You transplant right out of the Tubes. Bottom line, you use less water, less electricity and your back won't hurt.

Behind the Duffy Ducts are the two Deep Media Beds we showed you earlier only now they are growing massive amounts of cheery tomatoes. To recap, Food Forever Farms use Enhanced Deep Media Grow Beds and Duffy Ducts in place of traditinal Deep Media Grow Beds and Deep Water Culture Raft Systems. We like to think of ourselves as the Distruptors of the Disruption of Agriculture.

3. Stage 2 Vertical Duffy Duct System: So far we have discussed two of the most popular types of Grow Beds that are being used in the new agriculture, Deep Media Beds (DM) and Deep Water Culture (DWC). But there is one more type of Growing Environment that has to be described. It's called Nutrient Film Technique (NFT). Nutrient Film Technique Growing happens in narrow Channels like the ones you see in the photo below. If you go over to FarmTek.com to price out these Channels, you'll discover they are about $29.75 per 10 ft. Channel, and you have to pay extra for end caps and lids. You have to have the lids with the holes in them to hold the Net Pots, and they cost another $21.39, but they don't have the holes so you would have to pay the labor cost to cut the holes in the lids. So for one 10 ft. Channel and it's lid without holes, the cost is $51.14. They also sell arrays of Channels for less, but you can see the investment in these Channels alone for a large operation is huge. For example, a 6" Channel Array that is 30 ft. wide x 60 ft. long costs over $10,000.

They are configured for Horizontal growing with each Channel receiving the nutrient rich water individually. NFT has the advantage over DWC of using about one liter of water per minute flow through the Channel. The disadvantage of NFT is that due to the large Channel surface area to water ratio, the water can become heated during the transition from one end to the other. Long NFT troughs suffer from this as well as loss of nutrients, oxygen and sometimes a change in pH, as well as requiring considerable change in height from one end to the other. The slope of NFT is usually about 30 to 1. Another disadvantage to NFT is that if the water flow is interrupted for a period of time, the roots are no longer in water and the plants can suffer. NFT is usually limited to leafy green plants, but flowering plants like tomatoes have been successfully grown in them.

Our Improvements on these typical NFT’s are many. Firstly, Vertical Duffy Ducts have been designed to be placed in a near vertical configuration, which will allow you to grow more plants within a given horizontal space. We manufacture uniquely designed Channels that cost considerably less than what we described above, and the lid is not a separate piece of the component. We offer Vertical Growing in 4ft., 6ft., 8ft. and 10ft. high Channels with the built-in ease of planting and harvesting in a Greenhouse or a Growhouse. To view our Vertical Duffy Ducts, request a copy of our "How Food Forever Farms Work" (subject to an NDA).

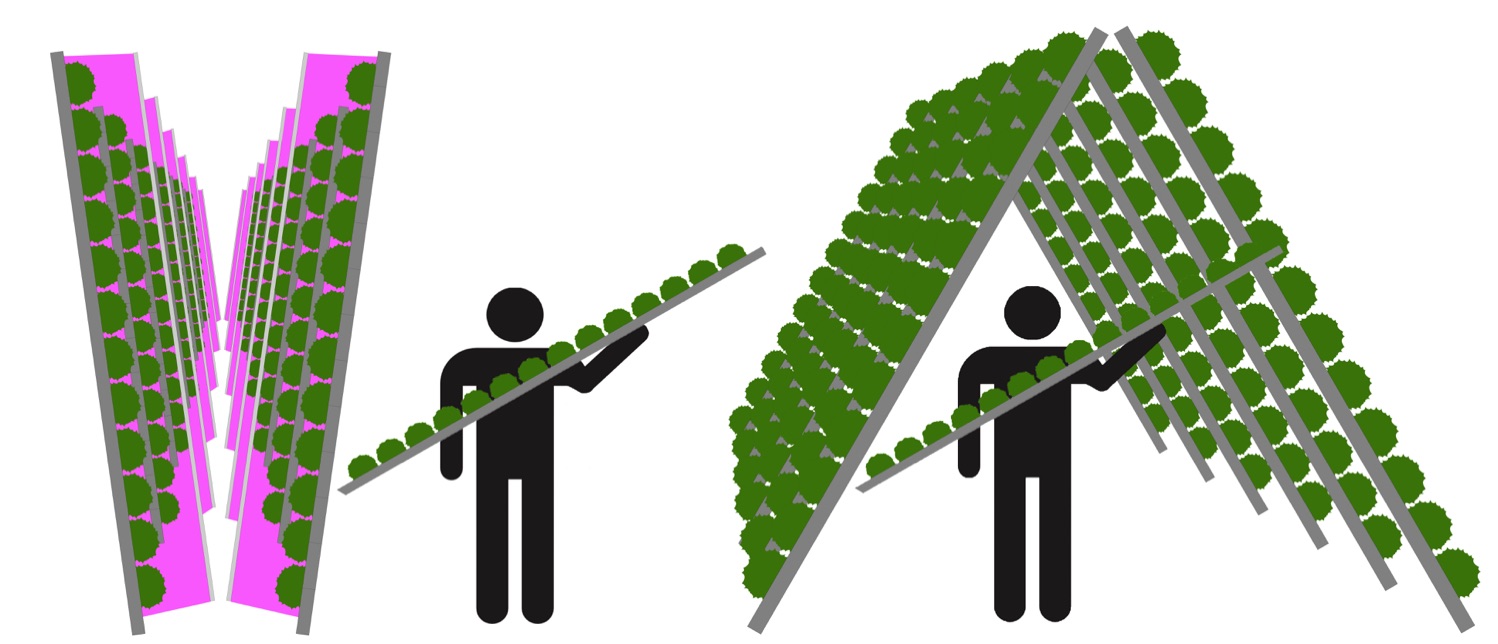

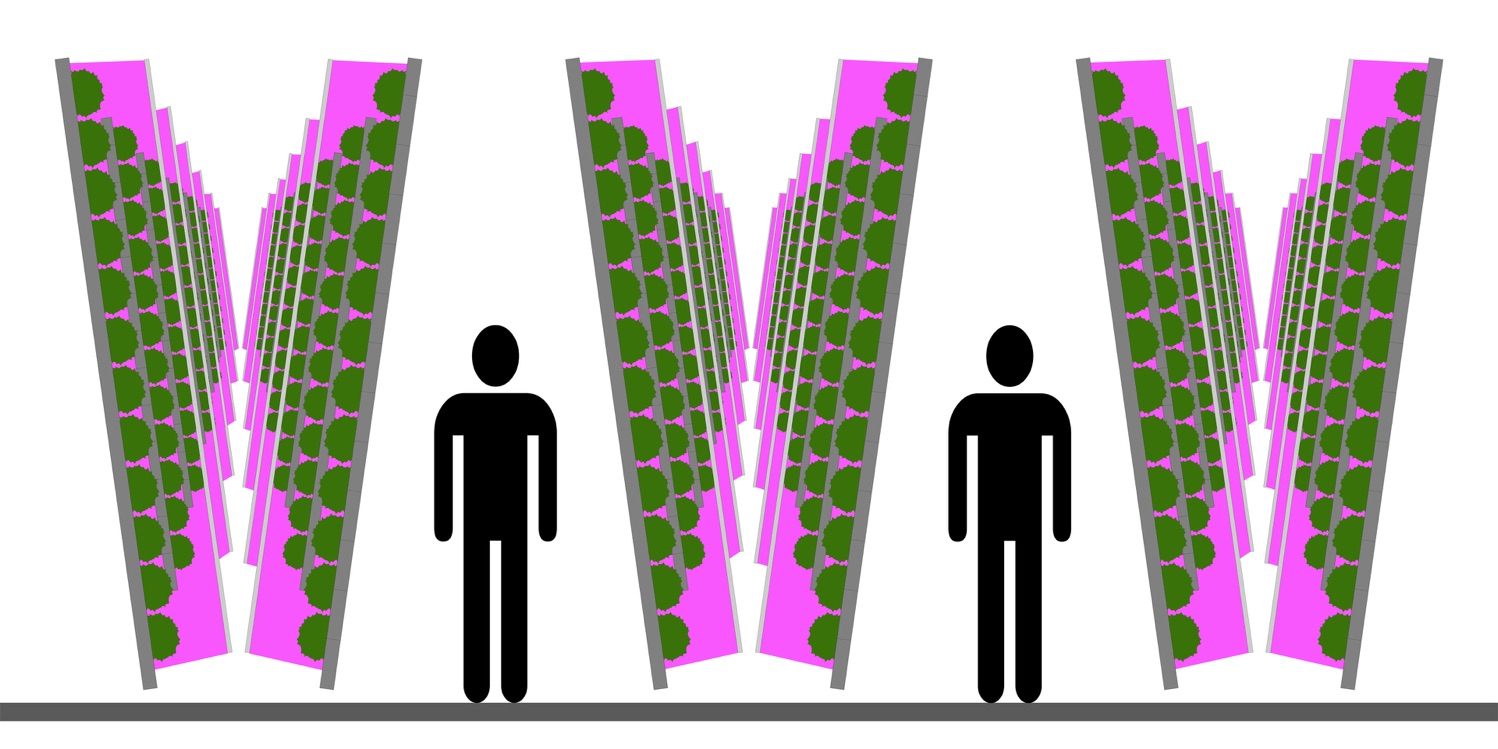

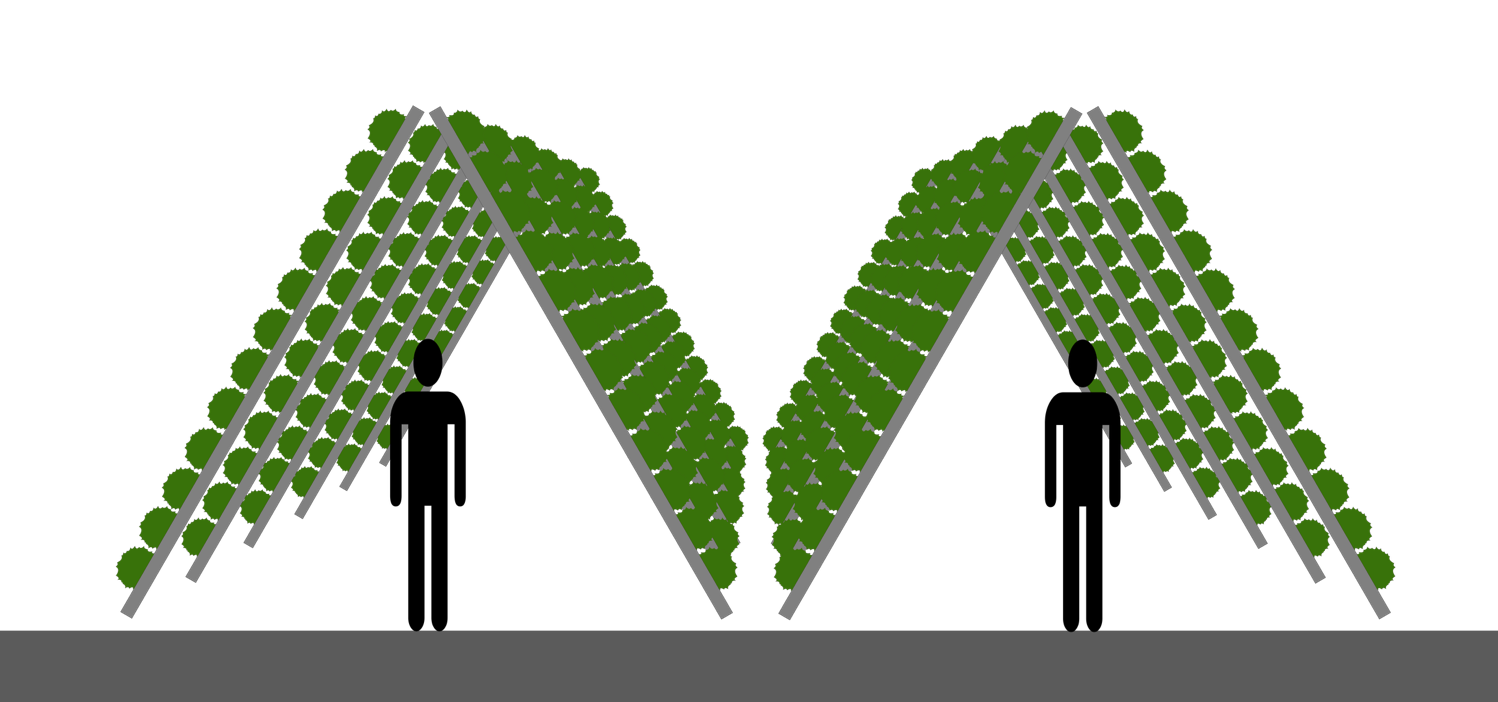

Below you see three Ilustrations of Vertical Duffy Ducts in both a Growhouse and a Greenhouse. We use the same Duffy Ducts for both growing locations, but as you will see below, there is a significant difference in how they are configured.

Below is an Illustration of a 70 Degree Vertical Duffy Duct System with LED Bar Lights for Indoor, Growhouse Growing. Notice the plants are facing each other within the Left & Right V-Shaped Configuration. The Ducts holding the Plants are inserted and removed from the back side of the V-Array for planting and harvesting. The Silouette Figures point to this location. This makes it possible to leave the LED Grow Light Bars undisturbed.

Below is an Illustration of a 60 Degree Vertical Duffy Duct System for Greenhouse Growing. Notice the plants are growing away from each other on the outside of the Left & Right Inverted V-Shaped Configurations. The Troughs holding the Plants are inserted and removed from the under-side of the Inverted V-Array, where the Silouette Figures are located. The Troughs are then placed on a work table where they can easily be harvested or replanted.

Below is an Illustration of a 70 Degree Vertical Duffy Duct V-Array for Warehouse Growing and a 60 Degree Inverted V-Array for Greenhouse Growing. The Silouette figures are removing or replacing individual Ducts into these Systems. In both cases, this happens from the back, but with the Warehouse V-Array System, the figure is outside of the Array and with the Greenhouse Inverted V-Array, the figure is under the Array.

The images below illustrate why you want to grow Lettuce and other Leafy Greens and Herbs like Basil, Bok Chow or Swiss Chard in Grow Beds that do not have Hydroton. The standard for these other types of Grow Beds are either Deep Water Culture (DWC) or Nutrient Film Technique (NFT), which are described below. Our BioPonic Earth Agri-Tech offers unique variations on these two other standard types of Growing Environments.

But first, witness the nightmare of Hydroton full of Leafy Green or Herb Roots below. Hydroton is expensive so you want to save every pebble, and that means dislodging each pebble from these roots. There is no way you could run a commercial operation that sells Leafy Greens and Herbs by only using Deep Media Beds.

4. The Fish Tanks: If you're running an Aquaponics System, you're going to need Fish Tanks, and it is important to understand they take up a lot of space. We often recommend the Fish Tanks and some of our other Agri-Tech Components be contained in a separate area from the Growing Area, but that depends entirely on your allotted space and budget.

Above is a 500 Gallon Fish Tank, which fits perfectly with two 4 ft. x 8 ft. Grow Beds. These Fish Tanks are made of powdered Polythylene Plastic and are resistant to impact, most corrosive chemicals and temperature extremes. The slippery surface make them easy to clean. It has a 6 ft. 8 inch diameter and is 30 inches high. The size of the Fish Tanks Depends on the size of the Custom System we are creating and the space that is available. Below is a photo of three of our 320 Gallon Fish Tanks with 37 huge Tilapia in two of them and fingerlings in the front Tank.

Although not critical, the Fish Tank size is a matter of convenience when considering human operators height and physical ability to be able to handle the removal of the mature fish. For this reason, we like to limit the height of the tanks to about four feet. The maximum diameter of the tanks can be 12 feet or more, but transportomg these larger Tanks becomes costly.

The number of tanks is also important in order to maintain a steady amount of fish weight in the system to produce a constant nutrient level for the plants. The greater the number of Fish Tanks with staged fish grow out, provides the most stable level of nutrients. The minimum number of Fish Tanks and fish grow out stages is about six. The maximum number of tanks is about twelve. With more Fish Tanks comes more maintenance, which increases labor.

Our Micro Food Forever Farm has four 320 Gallon Fish Tanks by a different manufacturer than the Fish Tanks we are now offering (hence, the color change). We can no longer get these 320 Gallon Tanks do to Supply Chain issues. Below is a photo of three of them.

5. The Fish: The Fish are a major component of an Aquaponics System. In fact, we call the Fish in their Fish Tanks the "Engine" of an Aquaponics System because without them, the System will not go. Tilapia is the fish of choice among Aquaponics farmers. It also happens to be the easiest fish to grow in an Aquaponics System (especially for beginners). The Tilapia is a tropical fish whose native home is Africa and the Nile River Basin in lower Egypt. They are perhaps the oldest farmed fish on the planet as there are documented accounts of them having been farmed as far back as ancient Egypt. One of the oldest accounts of Tilapia farming is a bas-relief that was found in a 4,000 year old Egyptian tomb showing Tilapia held in ponds. Tilapia was such an important food source for the ancient Egyptians that it has it’s own hieroglyph.

Due to this prolific farming of Tilapia, several hybrid species have been created as well. It’s full pouty lips, (many women have paid a pretty penny for lips like this) are the doorway of the nursery for a mother Tilapia who scoops up the fertilized eggs she laid in the nest built by the male and carries them in her mouth for 4-8 days. She continues to carry the newly hatched baby fish called “fry” for another 3-5 days.

At this point the fry hang out in schools all rushing back to the safety of these prominent lips when danger approaches. Tilapia growers are gifted with the beauty of observing this natural cycle right in the breeding Tank as adult female Tilapia spawn every 4-6 weeks.

Successful breeding and brooding of Tilapia is of utmost importance in a commercial Aquaponics Food Forever Farm operation as the fish play equally crucial dual roles. Firstly, their waste, once it is broken down into usable plant nutrients, provides the fertilizer necessary for the plants; and secondly, the fish themselves provide the lion’s share of the protein for the people eating the two products the farm provides, vegetables and fish. This means that a cycle of harvesting adult, plate-sized Tilapia must be balanced with breeding, brooding and growing out the Tilapia that are needed to fertilize and maintain the growth of the plants.

The breeding and brooding tank is where the breeding stock is kept and all the wonders of the creation of Tilapia life take place. Because the fingerlings and young Tilapia require so much protein for these early stages of growth, they are carnivores making it very important they be removed from the breeding tank immediately. Adult Tilapia require much less protein and, therefore, become mostly herbivores who do not eat their young.

5. Components For Aquaponics Systems Only: Below, you see 4 Logos that name 4 Unique Agri-Tech Components we often add to our Aquaponics (AP) Systems when we consult Farmer/Entrepreneurs and provide access to these Components as they build BioPonic Earth Aquaponics Food Forever Farms. The WET System helps create clear, clean water that is highly oxygenated. AquaHeat heats the Fish Tank or Tanks 24/7 without depending on expensive electric heaters. Dilution Solution provides a way to quickly and easily add your additives so they never overpower your AP System. The SIT automatically waters your Seedlings. You can get the details about how these Components work by reading our "How Food Forever Farms Work", available upon the receipt of a NDA.

6. Components often added to both Aquaponics and Nitraponics Systems: Below, you see Logos that name Unique Agri-Tech Compnents we add to our Aquaponics and Nitraponics Systems when we consult Farmer/Entrepreneurs and provide access to these Components as they build BioPonic Earth Food Forever Farms. Both of these Components assist in keeping the Water Clear and Clean.

The Solids Separation Biofiltration System (SSBS) allows the Farmer/Entrepreneur to leave the solids in the system, whether they are from added Fish Food (without the Fish) in the case of Nitraponics or from actual fish waste in the case of Aquaponics. These solids are mineralized in our SSBS System, and the increased nutrients due to the solids that are left in the System can grow about twice as many plants with the same number of fish and fish food.

The Nitrate Activator (NA) is an ingenious device that actually creates Nitrates. The Farmer/Entrepreneur puts in Fish Food or other high nitrogen content organic plant based feed stock and out comes Nitrates for his Aquaponics or Nitraponics System. This Component is still in R&D.

7. Trademarks and Food Forever Farm Patent-Pending Patent: The following Logos represent our Trademarks and Patent Pending Agri-Tech Intellectual Properties.

Aquaganic™ is our unique Trademarked name for all Products grown in BioPonic Earth Aquaponics Food Forever Farms. We have devoted an entire page to this Trademark, describing what it means and how to get your Aquaponics Food Forever Farm Certified by our sister company, AquaponicsUSA.

Nitraganic is our unique Trademark name for all Products grown in BioPonic Earth Nitraponics Food Forever Farms. (This Trademark is pending).

Rad-Shielded is our unique Trademark name for all Products grown in BioPonic Earth Food Foreve Farms. It reminds consumers that Fukushima's unstoppable and continuously escaping radiation is a fact of life making it far more healthy to grow food in protected enviornments like Food Forever Farms. (This Trademark is pending).

The following List of our Intellectual Property are being combined and defined by our Lawyer into a single Food Forever Farm, Patent-Pending Procress, and these Names are also included in our Pending Trademarks.

Duffy Duct (DD) is our unique Trademark name for our Stage 1 Horizontal and Stage 2 Vertical Duffy Duct Systems designed by Oliver Duffy. (This Trademaek is pending).

Water Enhancement Technology (WET) described above is a System that creates clear, clean water that is highly oxygenated.

Solids Separation Biofiltration System (SSBS), described above is in a combined Food Forever Farm Patent-Pending Process.

Nitrate Activator System (NAS), described above, is in a combined Food Forever Farm Patent-Pending Process.

Stage 2 Vertical Duffy Duct System, described above, is in a combined Food Forever Farm Patent-Pending Process.

Stage 1 Horizontal Duffy Duct System, described above is in a combined Food Forever Farm Patent-Pending Process.

These Farms can be any size starting with a Micro Food Forever Farm that has from 70. ft. to 1,000 sq. ft. or be large-scale food growing environments and housed in Greenhouse or Growhouse multi-bay complexes. They can be placed anywhere in local communities to make food accessible to the people without it having to travel thousands of food miles adding cost and time, which depletes taste and quality. Communities have access to healthy, locally grown food that is both fresh and delicious.

Aquaheat is the best way to heat Fish Tanks in an Aquaponics Greenhouse or Growhouse! It heats the Tanks & the Structure.

The Nitrate Activator

is still in R & D.

A Food Forever Farm is placed withn a Greenhouse or a Growhouse to grow Vegetables and Food Fish using proprietary BioPonic Earth Agri-Tech. The Farmer/Enrepreneur can choose to fertilize the plants with Fish effluent that is broken down into nutrient rich fertilizer for the plants by a process known as Nitrification. Or the Farmer/Entrepreneur can choose to fertilize the plants by converting high nitrogen content organic plant based feed stock into fertilizing nutrients. If Fish effluent is chosen, a second crop of Food Fish is raised as a protein source.

*At this critical time of possible Food Shortages in the U.S., we are only offering our Agri-Tech Licensing Agreements to Farmer/Entrpreneurs who want to build Aquaponics Food Forever Farms due to the importance of providing a protein source from their Farms with Food Fish.

Every Food Forever Farm is a Custom Design that is determined according to the answers to the questions listed above. But most Food Forever Farms will have the following Components:

1. Deep Media Hydroponic Grow Beds: There is nothing new and revolutionary about Deep Media Grow Beds. They are tried and true plant growing environments that work much like raised Beds do for soil Growers. Our Grow Beds sit on strong steel stands with botom shelves. They are placed at a comfortable height for planting and harvesting that is easy on the spine.

The rule of thumb for Deep Media Grow Bed depth is 12 inches deep (30 cm). The advantages of Deep-Media Grow Beds are many when you want to grow flowering plants.

Flowering plants are plants that grow fruits or vegetables after first producing a flower. Leafy Greens are also Flowering Plants, but that's another story. There is more media in Deep Media Beds to cultivate a greater amount of the friendly bacteria necessary to convert ammonia from the fish waste (if you're doing Aquaponics) BioDigested Fish Food (if you're doing Nitraponics) into nitrates for optimum plant growth; and that allows for higher fish stocking density (if you're doing Aquaponics).

The word “Media” describes the “Substrate” that is placed inside the Grow Bed to function in many capacities, one of which is to hold the plants that are growing in the Grow Bed. In Biology, a “Substrate, is the natural environment in which an organism lives, or the surface or medium on which an organism grows or is attached.” This is the perfect definition of the Media in a Grow Bed because there is a lot more growing in these Grow Beds than the plants, which brings us to the other very important function of the Media in a Deep Media Bed. The Media provide a place for the beneficial bacteria to attach themselves. And now we just entered the domain of biology.

Just like the Fish Tank, the Grow Bed is an Ecosystem unto itself. With the friendly bacteria attached to the Bed’s media, it functions as a Biofilter breaking down the fish waste as it passes through the Bed. Biofilters work by growing friendly bacteria on a substrate, like gravel; and here is where expanded clay has the advantage. Unlike gravel, expanded clay is porous and, therefore, rich with lots of surface area where these friendly bacteria live and consume the passing fish waste breaking it down into soluble nutrients that become available for use by the plants.

When the water is run through the Grow Bed, these transformed nutrients get taken up by the plants and the cleaned water is then returned to the fish ready for the next cycle. These cycles are called Flood and Drain cycles, which is a common term in the field.

The scientific name for the process described above is called “Nitrification”. From this process, Nitrates are created, which is what you want to end up with–a high Nitrate count while your Nitrite and Ammonia counts remain very low because they can bring toxicity (even death) to both your plants and especially your fish. So, one of the most important jobs of a Deep Media Grow Bed is to act as a Biofilter. In both Aquaponics and Nitraponics Systems, this is a necessary process as they could not properly function without a working Bio-filter.

So, the Deep Media Grow Bed grows natural, friendly bacteria as well as plants. Flowering plants require high Nitrate counts in order to put out their fruits and vegetables. We have made significant improvements on our Deep Media Beds as indicated by what you don't see. These improvements are hidden under the Hydroton. We share them in detail in our "How Food Forever™ Farms Work" document that is subject to an NDA.

Below are some custom built Deep Media Grow Beds which we put into our Demo Greenhouse that we converted from a porch that sits off the Living Room and Kitchen of our Arizona home. The windows on the right, look into the Living Room. The third of the Greenhouse that is not pictured has windows looking into the kitchen and contains our Vertical System of Duffy Ducts™(not shown and subject to an NDA) and our Stage 1 Horizontal Duffy Duct™ System (explained below). What you don't see is how we've improved Deep Media Grow Beds. That is revealed beneath the Hydroton and is explained in detail in our "How Food Forever™ Farms Work" Document.

Different types of Grow Beds grow different types of plants. When the second photo was taken, we did not have our Stage 2 Vertical Duffy Duct System built yet, so we planted lettuce in the Deep Media Beds. Deep Media Beds are best for Flowering Plants like Tomatoes, Peppers, Squash and Melons.

OR